FAQ

Macro Converter is a specially designed cogeneration furnace – a biomass furnace with an additional function. Thanks to its ability to achieve high temperatures it successfully converts various types of waste polymer products (plastics, rubber), with the process of pyrolysis, into pyrolysis oil while at the same time heating the space. It is an innovative and unique device that has a triple effect: it provides cheaper heating, helps remove harmful waste from the environment and third – has the ability to produce pyrolysis oil for further use. The triple function makes it innovative and unique in the market.

All types of fuel of bio origin are suitable. These is primarily firewood (beech, oak, hornbeam and all deciduous trees) as well as other wood (pine, spruce, fir and all conifers), agricultural residues – corn, fruit stones, nut shells, grape remains and the most caloric residue: olive pomace, wood remains that we find all around us (discarded furniture, boxes, pallets, construction carpentry etc.).

While generating heat, a pyrolysis process, may or may not be performed. It is done by pyrolysis of household packaging plastic. Then the furnace has the function of a device of high energy efficiency with the production of fuel.

Macro Converter helps to preserve the environment by processing the collected waste, especially plastic materials. According to existing data1, more plastics have been produced in the last ten years than in the whole century. Also, although we usually use an ordinary bag only for a short time, in nature it decomposes up to 1000 years2. With the help of Macro Converter, plastic can be removed from nature and converted into pyrolysis oil suitable for further use.

As all devices that achieve heating by burning different fuels, the use of Macro Converter also releases gas. Burning dry wood does not cause harmful effects. In fact, its combustion is less harmful than the process of decomposition in the open or rotting. During decay, methane is generated that has a higher greenhouse potential than carbon monoxide released by combustion. While performing its basic function of heating the space, Macro Converter at the same time melts and thermally decomposes the plastic in a vessel called a retort at a high temperature without the presence of air.

The combustion process is automatic and controlled by lambda probes and computers, and the result of the pyrolysis process are energy sources: pyrolysis oil (also called synthetic diesel, which is a mixture of various refinery products – gasoline, jet fuel, tar…), pyrolysis gas and solid residue, pyrolysis coal. With the described process plastic is being removed from the environment, and during the combustion of wood biomass, all emissions are within the legally prescribed values.

Pyrolysis oil can be used directly without further processing as a substitute for fuel oil or addition to diesel in robust engines such as electric generators, tractors, ships and so on. The oil can be delivered to the industry (smaller refinery) for further processing. Such capillary or decentralized production dates back to the last century, and its advantages are numerous: less pollution from large plants, lower risks for the environment, self-sustainability, household income etc.

By using, for example, 20 kilograms (as it fits in a container – retort) of plastic packaging (plastic bottles, bags, etc.), 14.5 liters of pyrolytic oil is produced. In a day of heating a space up to 1000 m2 big, in approximately 12 hours, two cycles can be done resulting in 30 liters of pyrolysis oil. It takes around 6 hours for a cycle. The price of such produced fuel should be equal to the price of raw oil on the world market.

The heating season usually lasts 6 months or 180 days. If we take into account that production won’t last all 180 days but for example around 150 days, the total profit would be 43,500 kuna for a household or business subject that owns Macro Converter. In Croatia alone, 390,500,000 kilograms of waste plastic are generated annually, from which 292,875,000 liters of pyrolysis oil can be produced3.

By using, for example, 20 kilograms (as it fits in a container – retort) of plastic packaging (plastic bottles, bags, etc.), 14.5 liters of pyrolytic oil is produced. In a day of heating a space up to 1000 m2 big, in approximately 12 hours, two cycles can be done resulting in 30 liters of pyrolysis oil. It takes around 6 hours for a cycle. The price of such produced fuel is up to 10 kuna per liter on the free market.

The heating season usually lasts 6 months or 180 days. If we take into account that production won’t last all 180 days but for example around 150 days, the total profit would be 43,500 kuna for a household or business subject that owns Macro Converter. In Croatia alone, 390,500,000 kilograms of waste plastic are generated annually, from which 292,875,000 liters of pyrolysis oil can be produced3.

The ideal buyers are homeowners who have space to accommodate a standard 20-foot container with a stove and chip storage of 12m2, medium and small businesses as well as all institutions or businesses located in facilities up to 1000m2.

First of all, it is an innovative product which, unlike similar wood-burning stoves, has a triple function – it provides cheap thermal energy, it helps the environment and produces pyrolysis oil. Energy prices are rising from year to year, and self-sustainability should be the main goal of individuals and the states. The great advantage of Macro Converter is the fact that it is kind of an ecological magic wand that at the state level provides the opportunity to subsidize the production of pyrolysis oil to citizens and buy energy, and thus control the market and become self-sufficient. At the same time, it removes plastics which is one of the leading polluters from the environment.

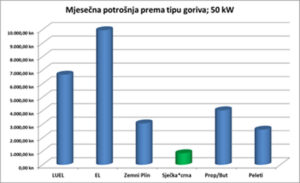

Below is a table showing the various energy sources for household consumption up to 500m2.

It is common for a similar type of furnace to achieve a return on total investment in 4 to 6 years. Using Macro Converter the return on total investment occurs within 3 to 4 years.

It should be noted that at the moment Macro Converter has no competition and that a product with the same functions does not exist on the market. Even in the case of the emergence of new products inspired by Macro Converter, we prefer years of research and troubleshooting beginners.

Macro Converter was created with aim of creating a product that will provide an energy efficient solution, solve problem of energy supplying, product that is self-sustainable and contributes to the global goals – removing plastics from the environment. Our goal was to produce a multifunctional product that brings savings and a greener future for future generations.